Inflation Systems

Standard Inflation System Specifications

A single packaged unit incorporating inflation fan, backup power source and pre-wired control system. Shipped fully tested. Requires power and fuel connections to be operational. Emergency engine may be deleted when multiple units are used on the same structure.

A single packaged unit incorporating both inflation fan, backup power source and pre-wired control system. Shipped fully tested. Needs only power and fuel connections to be operational. Emergency engine may be deleted in redundant units when multiples are used on a structure.

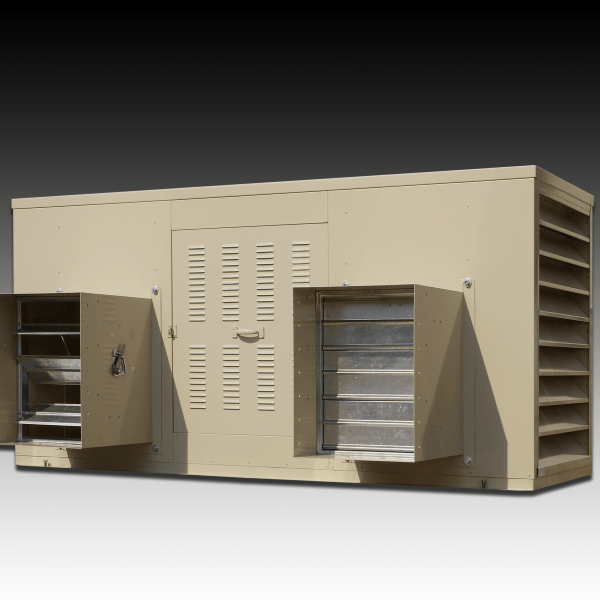

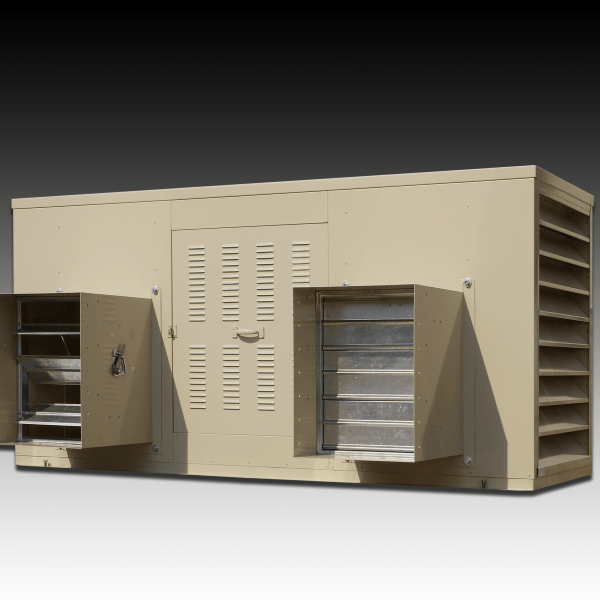

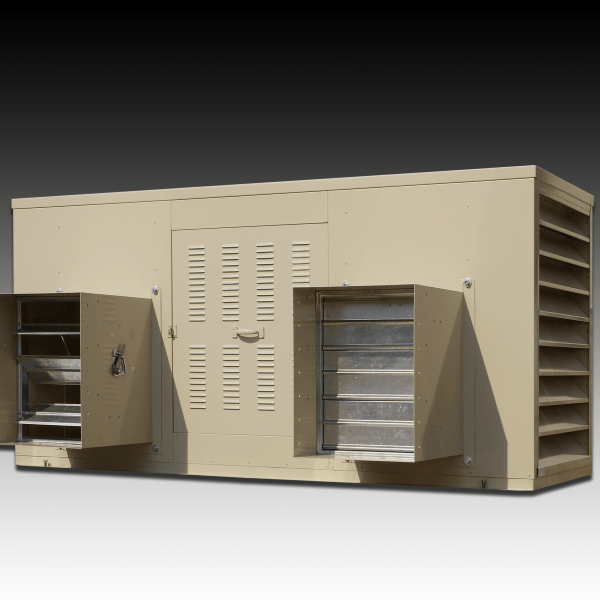

Housing

Base and housing fabricated from heavy gauge galvanized steel.

Top corners are radius to prevent potential fabric damage.

Louvered motor compartment doors.

Opposed blade balancing dampers mounted in discharge ducts.

Primed and powder coated.

Lifting eyes.

Fans

Backwardly inclined airfoil bladed wheels exhibit non-overloading horsepower characteristics, low noise generation and stable performance over the entire pressure curve.

Wheels are dynamically balanced in two-planes.

All bearings have remote grease lines.

Heavy gauge welded construction.

Drives & Motors

Motors are high efficiency ODP type, mounted on adjustable bases, with “B” V-belt fan drives.

Emergency backup engine is industrial grade, mounted on adjustable base, equipped with heavy duty centrifugal clutch and double “B” V-belt drive to secondary fan.

Available fuels are LP and natural gas. Diesel optional.

Control Panel

Enclosure: Carries NEMA 4-12 label - with disconnect switch.

Indicators: Building pressure gage – Status lights for control power and building pressure.

Switches and modes of operation - Primary fan: ON-Off, Secondary Fan: AUTO-OFF-ON, Emergency engine: TEST-AUTO-MAINTENANCE, Heat: ON-OFF.

Model 24-1

A single packaged unit used as a backup to the primary inflation source. The system includes a 24″ inflation fan, an internal combustion engine and a pre-wired control system.

A single packaged unit used as a backup to the primary inflation source. This system includes a 24″ inflation fan, an internal combustion engine and a pre-wired control system. Shipped fully tested. Needs only power and fuel connections to be operational.

Housing

Base and housing fabricated from heavy gauge galvanized steel.

Top corners are radius to prevent potential fabric damage.

Louvered motor compartment door.

Intake louver equipped with fabric back draft dampers for noiseless operation.

Opposed blade balancing damper mounted in discharge duct.

Primed and powder coated.

Lifting eyes.

Fans

Heavy gauge welded construction.

Backwardly inclined wheel exhibit non-overloading characteristics, low noise generation and stable performance over the entire pressure curve.

Wheel is dynamically balanced in two-planes.

All bearings have remote grease lines.

Drives & Motors

Emergency backup engine is industrial grade, mounted on adjustable base, equipped with heavy duty centrifugal clutch and double “B” V-belt drive to fan.

Standard fuels are LP and natural gas. Diesel optional.

Control Panel

Enclosure: Carries NEMA 4-12 label - with disconnect switch.

Indicators: Building pressure gage – Status lights for control power and building pressure.

Engine starts when pressure drops below set point or when electrical power is lost (requires connection to primary inflation electrical supply).

Switches & modes of operation - Emergency engine: TEST-AUTO-MAINTENANCE.

Performance Capability (example) 6,932 cfm @ 1.5″ wc, 1,176 rpm requires 2.79 bhp.

Model 24-2

A single packaged unit incorporating both primary and secondary inflation fans, a backup power source and a pre-wired control system.

A single packaged unit incorporating both primary and secondary inflation fans, backup power source and pre-wired control system. Shipped fully tested. Needs only power and fuel connections to be operational.

Housing

Base and housing fabricated from heavy gauge galvanized steel.

Top corners are radius to prevent potential fabric damage.

Louvered motor compartment doors.

Intake louvers equipped with fabric back draft dampers for noiseless operation.

Opposed blade balancing dampers mounted in discharge ducts.

Primed and powder coated.

Lifting eyes.

Fans

Backwardly inclined airfoil bladed wheels exhibit non-overloading horsepower characteristics, low noise generation and stable performance over the entire pressure curve.

Wheels are dynamically balanced in two-planes.

All bearings have remote grease lines.

Drives and Motors

Motors are high efficiency ODP type, mounted on adjustable bases, with “B” V-belt fan drives.

Auxiliary backup engine is industrial grade, mounted on adjustable base, equipped with heavy-duty centrifugal clutch and double “B” V-belt drive to secondary fan.

Standard fuels, natural and LP gas. Diesel optional.

Control Panel

Enclosure: Carries NEMA 4-12 label - with disconnect switch.

Indicators: Building pressure gage – Status lights for control power and building pressure.

Switches and modes of operation: Primary fan: ON-OFF, Secondary Fan: AUTO-OFF-ON, Emergency engine: TEST-AUTO-MAINTENANCE.

Performance Capability: Call for fan curves for your specific requirements.

Model 30-1

A single packaged unit including an inflation fan, an auxiliary power source and a pre-wired control system. The motor is a high efficiency ODP type, mounted on an adjustable base, with “B” V-belt drives to the fan.

A single packaged unit incorporating an inflation fan, an auxiliary power source and a pre-wired control system. Shipped fully tested, needs only power and fuel connections to be operational.

Housing

Base and housing fabricated from heavy gauge galvanized steel.

Top corners are radius to prevent potential fabric damage.

Louvered motor compartment door.

Intake louver equipped with fabric back draft damper for noiseless operation.

Opposed blade balancing damper mounted in discharge duct.

Primed and powder coated.

Lifting eyes.

Fans

Heavy gauge welded construction.

Backwardly inclined airfoil bladed wheel exhibit non-overloading horsepower characteristics, low noise generation and stable performance over the pressure curve.

Wheel is dynamically balanced in two-planes.

All bearings have remote grease lines.

Drives & Motors

Motor is a high efficiency ODP type, mounted on adjustable base, with “B” V-belt fan drives.

Auxiliary backup engine is industrial grade, mounted on adjustable base, equipped with heavy duty centrifugal clutch and double “B” V-belt drive to fan.

Standard fuels are LP and natural gas. Diesel optional.

Control Panel

Enclosure: Carries NEMA 4-12 label - with disconnect switch.

Indicators: Building pressure gage and status lights for control power and building pressure.

Switches and modes of operation: Fan: AUTO-OFF–ON, Heat ON-OFF, Auxiliary engine: TEST-AUTO-MAINTENANCE.

Model 30-2

A single packaged unit incorporating both primary and secondary inflation fans, backup power source and pre-wired control system.

A single packaged unit incorporating both primary and secondary inflation fans, backup power source and pre-wired control system. Shipped fully tested, needs only power and fuel connections to be operational.

Housing

Base and housing fabricated from heavy gauge galvanized steel.

Top corners are radius to prevent potential fabric damage.

Louvered motor compartment doors.

Intake louvers equipped with fabric back draft dampers for noiseless operation.

Opposed blade balancing dampers mounted in discharge ducts.

Primed and powder coated.

Lifting eyes.

Fans

Backwardly inclined airfoil bladed wheels exhibit non-overloading horsepower characteristics, low noise generation and stable performance over the entire pressure curve.

Wheels are dynamically balanced in two-planes.

All bearings have remote grease lines.

Heavy gauge welded construction.

Drives & Motors

Motors are high efficiency ODP type, mounted on adjustable bases, with “B” V-belt fan drives.

Emergency backup engine is industrial grade, mounted on adjustable base, equipped with heavy duty centrifugal clutch and double “B” V-belt drive to secondary fan.

Available fuels are LP and natural gas. Diesel optional.

Control Panel

Enclosure: Carries NEMA 4-12 label - with disconnect switch.

Indicators: Building pressure gage - Status lights for control power and building pressure.

Switches and modes of operation - Primary fan: ON-OFF, Secondary Fan: AUTO-OFF-ON, Heat: ON-OFF, Auxiliary engine: TEST-AUTO-MAINTENANCE.

Performance Capability (per fan): 10,906 cfm @ 1.5″ wc, 990 rpm requires 4.39 bhp.

Model 36-1

A single packaged unit including an inflation fan, an auxiliary power source and a pre-wired control system. The motor is a high efficiency ODP type, mounted on an adjustable base, with “B” V-belt drives to the fan.

A single packaged unit incorporating an inflation fan, an auxiliary power source and a pre-wired control system. Shipped fully tested, needs only power and fuel connections to be operational.

Housing

Base and housing fabricated from heavy gauge galvanized steel.

Top corners are radius to prevent potential fabric damage.

Louvered motor compartment door.

Intake louver equipped with fabric back draft damper for noiseless operation.

Opposed blade balancing damper mounted in discharge duct.

Primed and powder coated.

Lifting eyes.

Fans

Heavy gauge welded construction.

Backwardly inclined airfoil bladed wheel exhibit non-overloading horsepower characteristics, low noise generation and stable performance over the pressure curve.

Wheel is dynamically balanced in two-planes.

All bearings have remote grease lines.

Drives & Motors

Motor is a high efficiency ODP type, mounted on adjustable base, with “B” V-belt fan drives.

Auxiliary backup engine is industrial grade, mounted on adjustable base, equipped with heavy duty centrifugal clutch and double “B” V-belt drive to fan.

Standard fuels are LP and natural gas. Diesel optional.

Control Panel

Enclosure: Carries NEMA 4-12 label - with disconnect switch.

Indicators: Building pressure gage and status lights for control power and building pressure.

Switches and modes of operation: Fan: AUTO-OFF–ON, Heat ON-OFF, Auxiliary engine: TEST-AUTO-MAINTENANCE.

Model 36-2

A single packaged unit incorporating both primary and secondary inflation fans, backup power source and pre-wired control system.

A single packaged unit incorporating both primary and secondary inflation fans, backup power source and pre-wired control system. Shipped fully tested, needs only power and fuel connections to be operational.

Housing

Base and housing fabricated from heavy gauge galvanized steel.

Top corners are radius to prevent potential fabric damage.

Louvered motor compartment doors.

Intake louvers equipped with fabric back draft dampers for noiseless operation.

Opposed blade balancing dampers mounted in discharge ducts.

Primed and powder coated.

Lifting eyes.

Fans

Backwardly inclined airfoil bladed wheels exhibit non-overloading horsepower characteristics, low noise generation and stable performance over the entire pressure curve.

Wheels are dynamically balanced in two-planes.

All bearings have remote grease lines.

Heavy gauge welded construction.

Drives & Motors

Motors are high efficiency ODP type, mounted on adjustable bases, with “B” V-belt fan drives.

Emergency backup engine is industrial grade, mounted on adjustable base, equipped with heavy duty centrifugal clutch and double “B” V-belt drive to secondary fan.

Available fuels are LP and natural gas. Diesel optional.

Control Panel

Enclosure: Carries NEMA 4-12 label - with disconnect switch.

Indicators: Building pressure gage - Status lights for control power and building pressure.

Switches and modes of operation - Primary fan: ON-OFF, Secondary Fan: AUTO-OFF-ON, Heat: ON-OFF, Auxiliary engine: TEST-AUTO-MAINTENANCE.

Performance Capability (per fan): 10,906 cfm @ 1.5″ wc, 990 rpm requires 4.39 bhp.